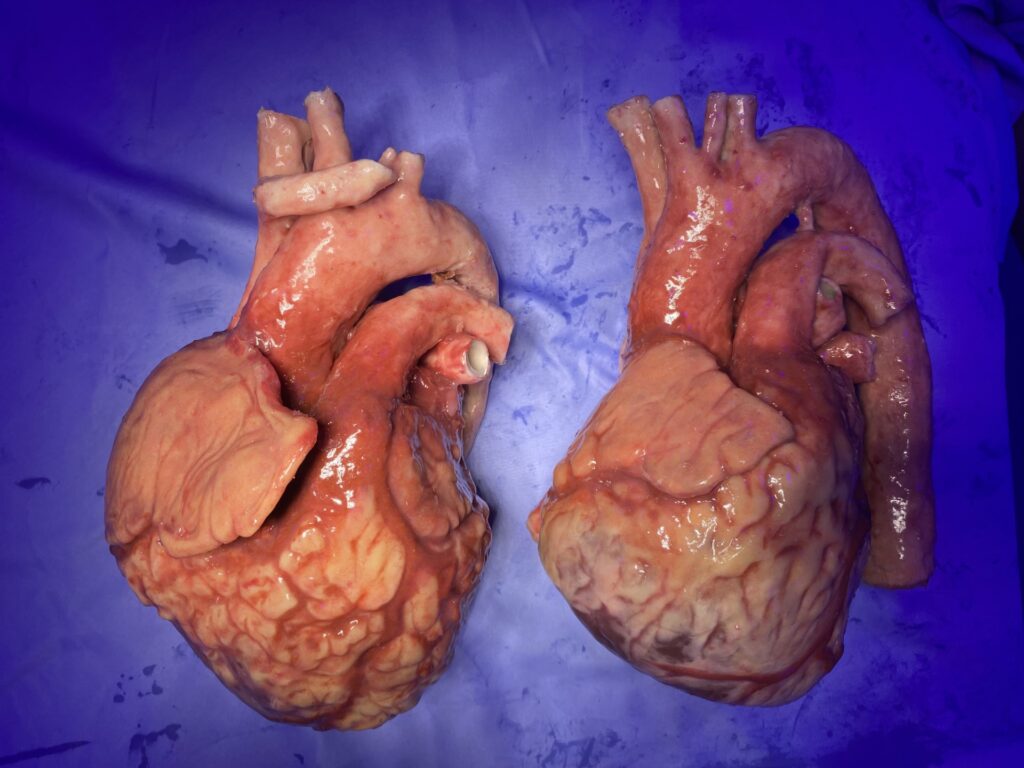

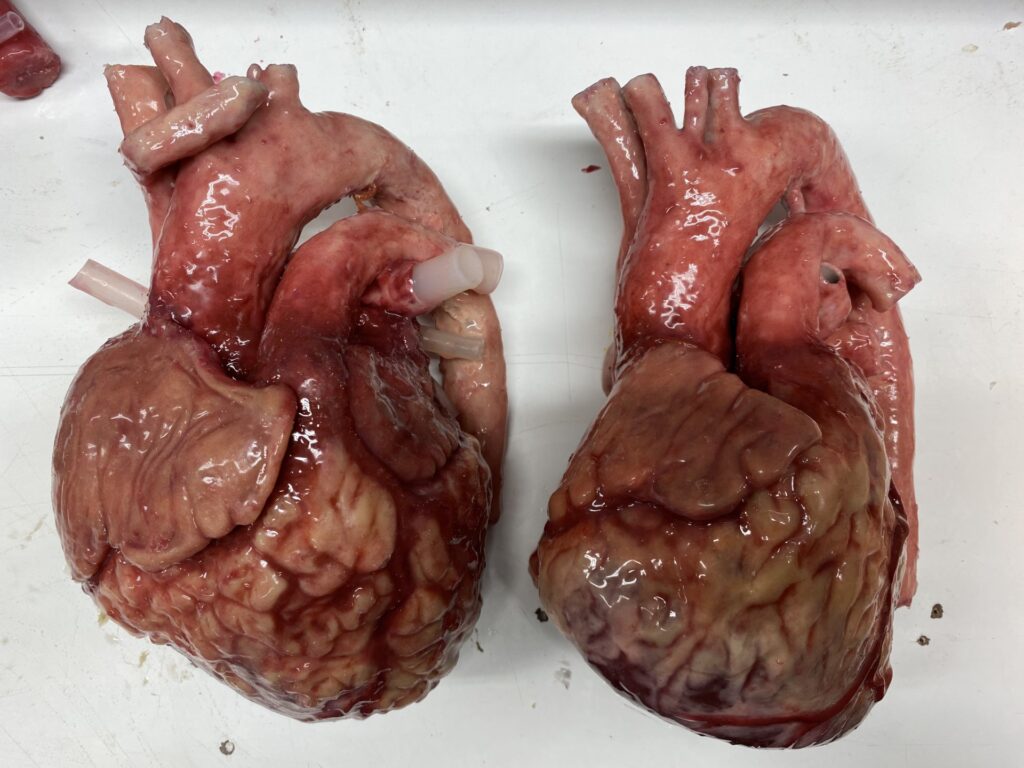

Artificial hearts and lungs, designed to mimic real organs in their diseased states, have been developed using 3D printing.

These lifelike models serve as invaluable tools for training surgeons in transplantation procedures.

The models, created by experts at Nottingham Trent University (NTU) in the UK, are made from silicone gels, fabrics and fibres.

They will allow surgeons to learn how to implant a healthy donor heart of a different size and shape to the diseased one.

Under the guidance of senior research fellow Richard Arm, a senior research fellow in the Nottingham School of Art & Design, scan data obtained from a heart failure patient and a healthy donor heart have been utilised to create meticulously detailed 3D models.

These models are invaluable for surgeons, enabling them to rehearse heart transplant procedures with unprecedented realism and precision.

Featuring the tactile qualities of human hearts, with differing levels of tissue hardness, the models will allow surgeons to practice incisions through the pericardium and the blood vessels which connect the heart to the lungs and the rest of the body.

The models feature bleeding vessels to simulate the experience of clamping them to stem any blood flow before incisions are made to remove the diseased organ.

The new heart can be sutured into place with real surgical instruments, and the process can then be repeated to allow for multiple mock operations, as the models are repairable and reusable.

Richard of the Nottingham School of Art & Design, said: ‘The aim is to allow surgeons to learn the technical aspects of organ transplant surgery and experience the tactile aspects of removing a failing heart and connecting a different healthy one, identifying and suturing the vessels that keep the donor heart in place.

‘This technology can simulate bleeding like a normal heart to provide the actual experience and limited visibility that surgeons must face on the operating table. The model is designed to be affordable, reusable, and portable, maximising access to the technology and allowing for increased risk-free training opportunities for transplant surgeons around the country.’

In an interview on the Nottingham University website, Richard Arm said: ‘One day, during my time as a technician, a surgeon approached me and asked if it was possible to create 3D models of internal human organs. He explained to me that trainee surgeons often don’t have a lot of time to practice new procedures and that human cadavers are not widely available to practice on.

‘I told him I’d never considered how to make human organs before but that I would find a way to help him. The result was a mix of traditional life casting and silicone casting, using materials that were familiar to me – but in a combination I’d never used before. I was fascinated by the potential of this work.’

Richard then looked for better ways to imitate human tissue to discover the process called ‘medical modelling’, which was missing a fundamental step: turning a patient’s scan data into a 3D-printed organ replica that looks and feels like a real human organ.

Through extensive research, he eventually figured it out.

‘Now, I use medical scan data, 3D printers and traditional skills to make biological imitations of human anatomy that look and feel real enough to practice surgery.

Surgeons can plan surgeries, as well as rehearse and teach procedures safely, reducing the risk of complications and even death. An exciting future lies ahead for me – new collaborations with international corporations leading the way in robotic surgery and implantable devices that will help surgeons of the future learn their skills in risk-free environments.’.

The project was funded by Freeman Heart and Lung Transplant Association and was presented at the Society for Cardiothoracic Surgery in March.

You can view a video of their use here.